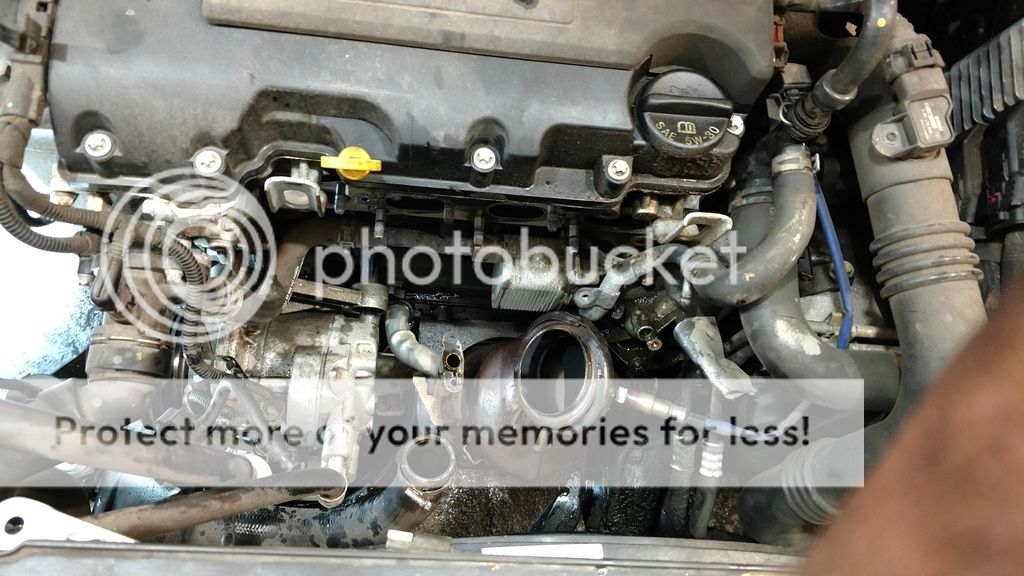

I have a 2012 LT with ~96K miles on it. The wastegate is done and I am getting ready to replace it.

Question 1

I am wondering if the '16 and up turbos are a direct swap and offer any benefits over the '11-'15 turbos. It is a nightmare researching these Garrett turbos. I tried reaching out to Garrett, but they wouldn't share anything with me since they are for GM.

Question 2

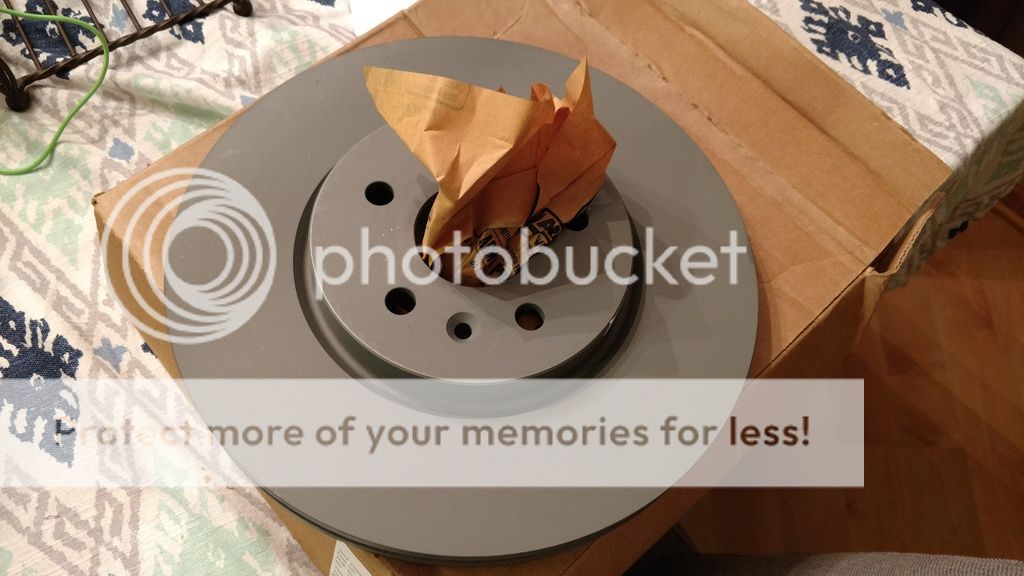

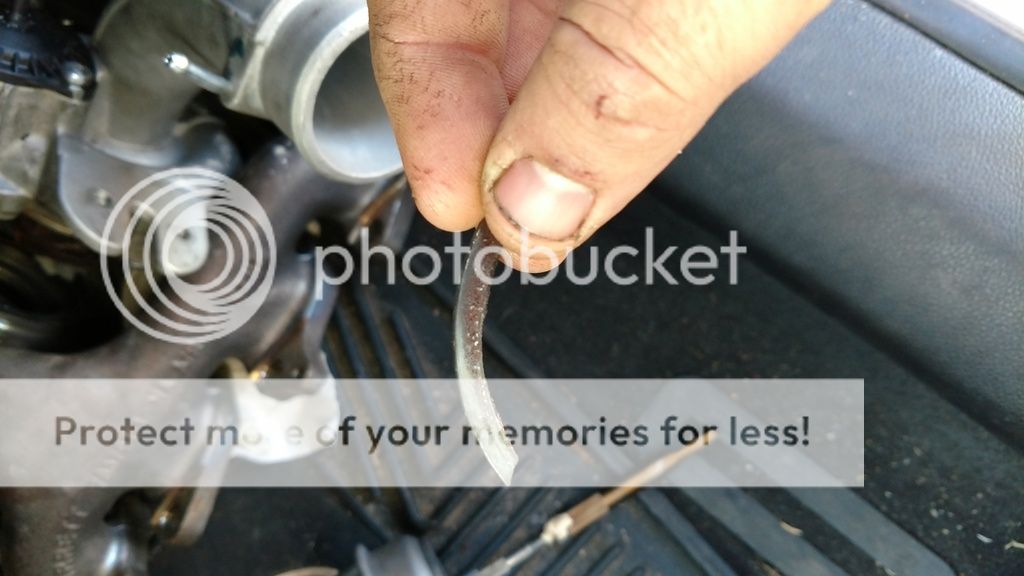

What all should I be replacing while I am in there? I have read about the oil lines and plan on doing those, but is there anything else that needs to be done? Gaskets, vacuum lines, clamps, etc?

Any help would be greatly appreciated.

Question 1

I am wondering if the '16 and up turbos are a direct swap and offer any benefits over the '11-'15 turbos. It is a nightmare researching these Garrett turbos. I tried reaching out to Garrett, but they wouldn't share anything with me since they are for GM.

Question 2

What all should I be replacing while I am in there? I have read about the oil lines and plan on doing those, but is there anything else that needs to be done? Gaskets, vacuum lines, clamps, etc?

Any help would be greatly appreciated.